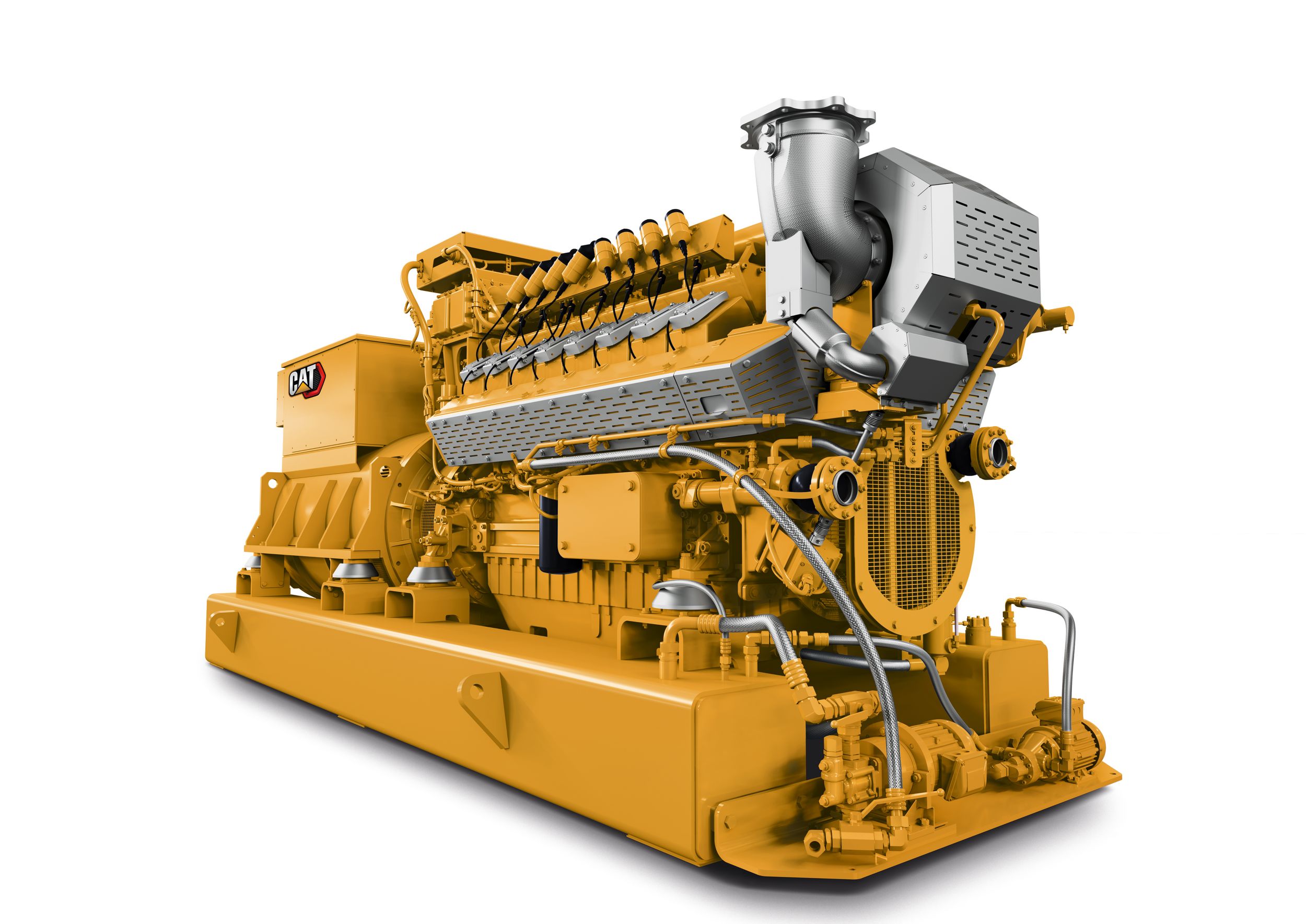

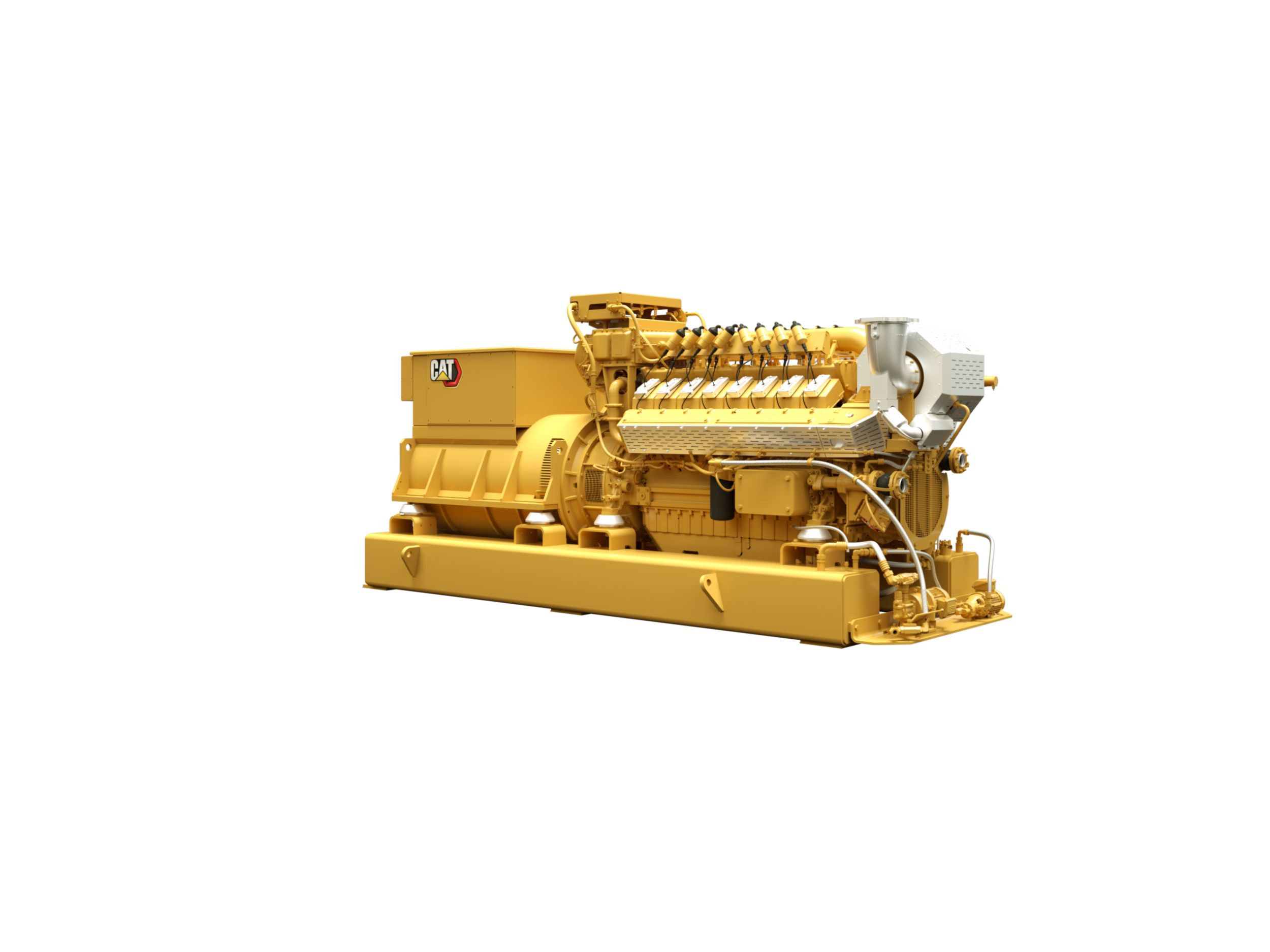

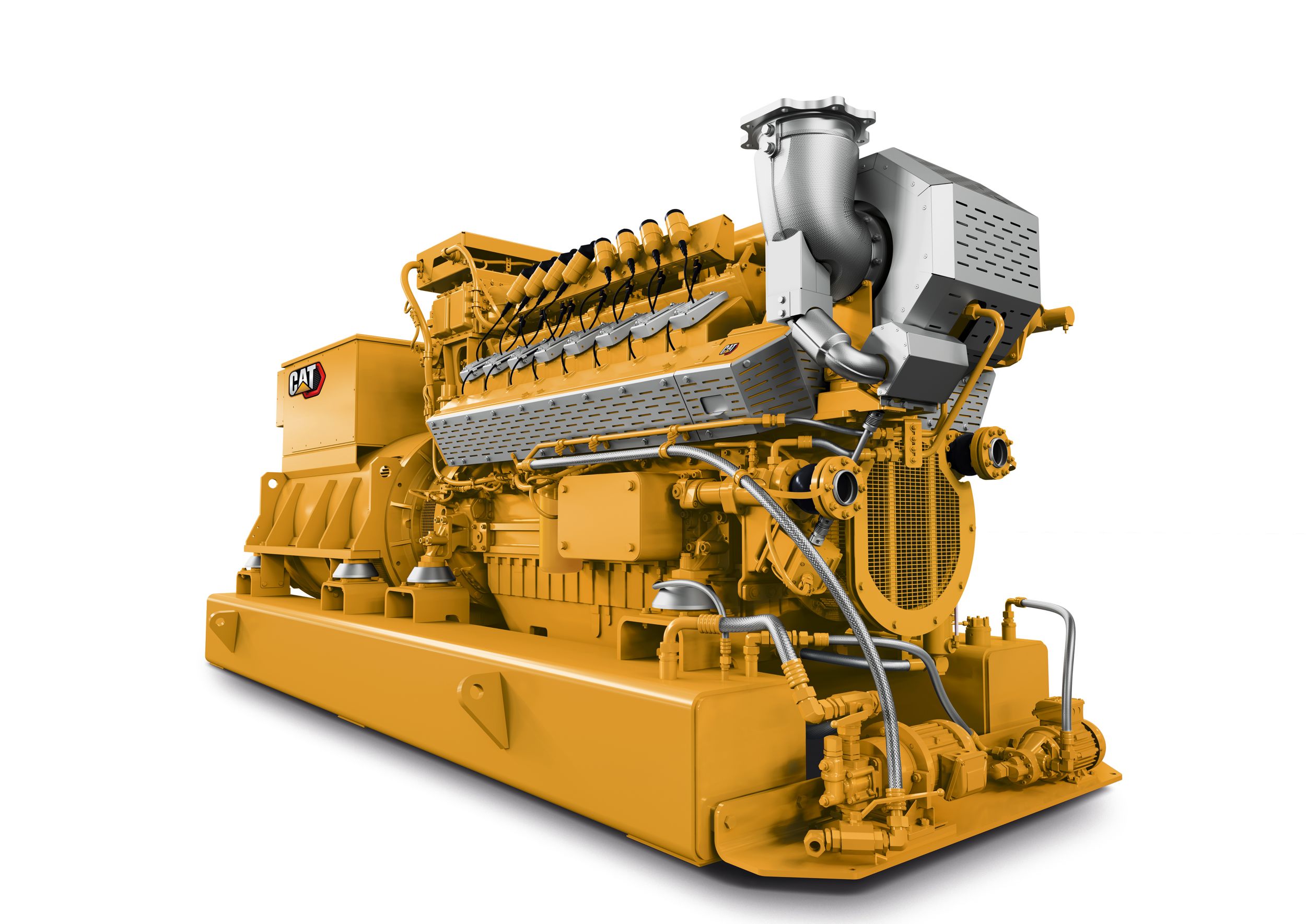

Continuous Rating

1000 ekW @1.0pf

Fuel Type

Natural Gas, Hydrogen Blend (up to 25%)

Maximum Electrical Efficiency

41.50%

Frequency

50 Hz

RPM

1500 rpm

Natural Gas Rating

1000