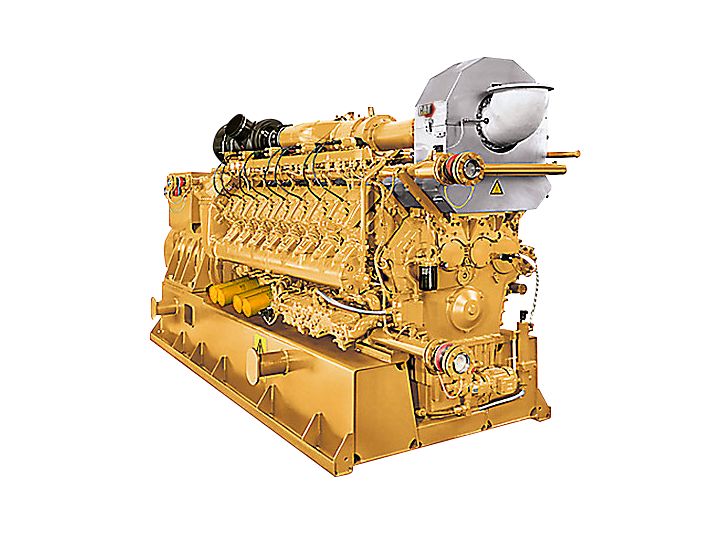

Continuous Rating

1560 ekW @1.0pf

Fuel Type

Natural Gas, Biogas, Coal Gas

Maximum Electrical Efficiency

43.30%

Frequency

50 or 60 Hz

RPM

1500 or 1800 rpm