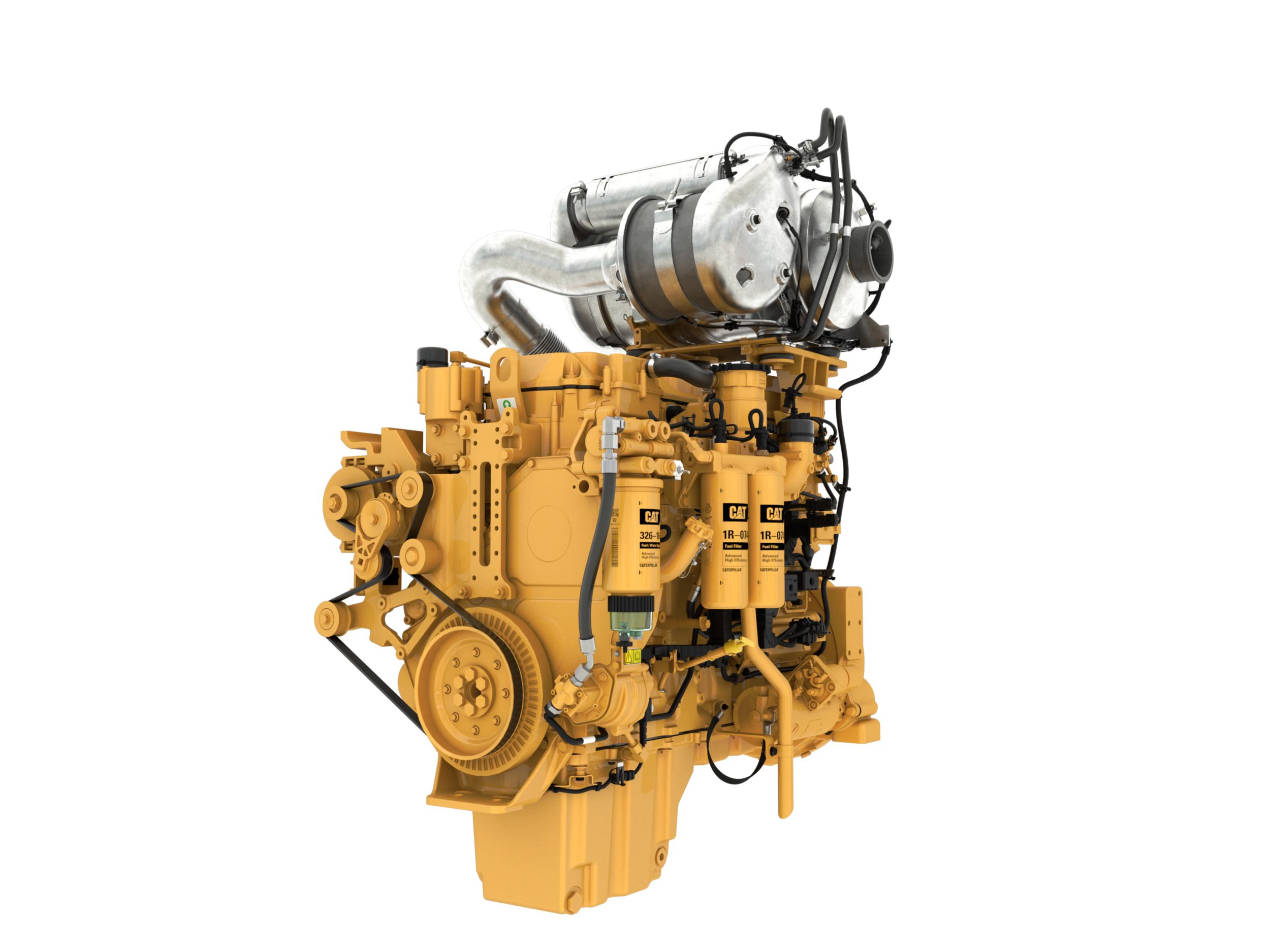

Maximum Power

577HP

Maximum Torque

1943lb-ft @ 1400 rpm

Rated Speed

1800-2100 rpm

Minimum Power

456HP